How Automation is Transforming Manufacturing Industries

6 July 2025

Let’s face it—manufacturing will never be the same again. Gone are the days of rows of workers assembling products by hand, with stopwatches ticking away and supervisors pacing back and forth. In today’s fast-paced, tech-driven world, automation has taken center stage in the manufacturing world—and it’s not slowing down anytime soon.

So what’s really going on? How is automation changing the game so drastically in manufacturing industries across the globe? Buckle up, because we’re about to dive deep into this transformation that’s both exciting and, let’s be honest, a little intimidating too.

The Evolution of Manufacturing: From Manual to Machine

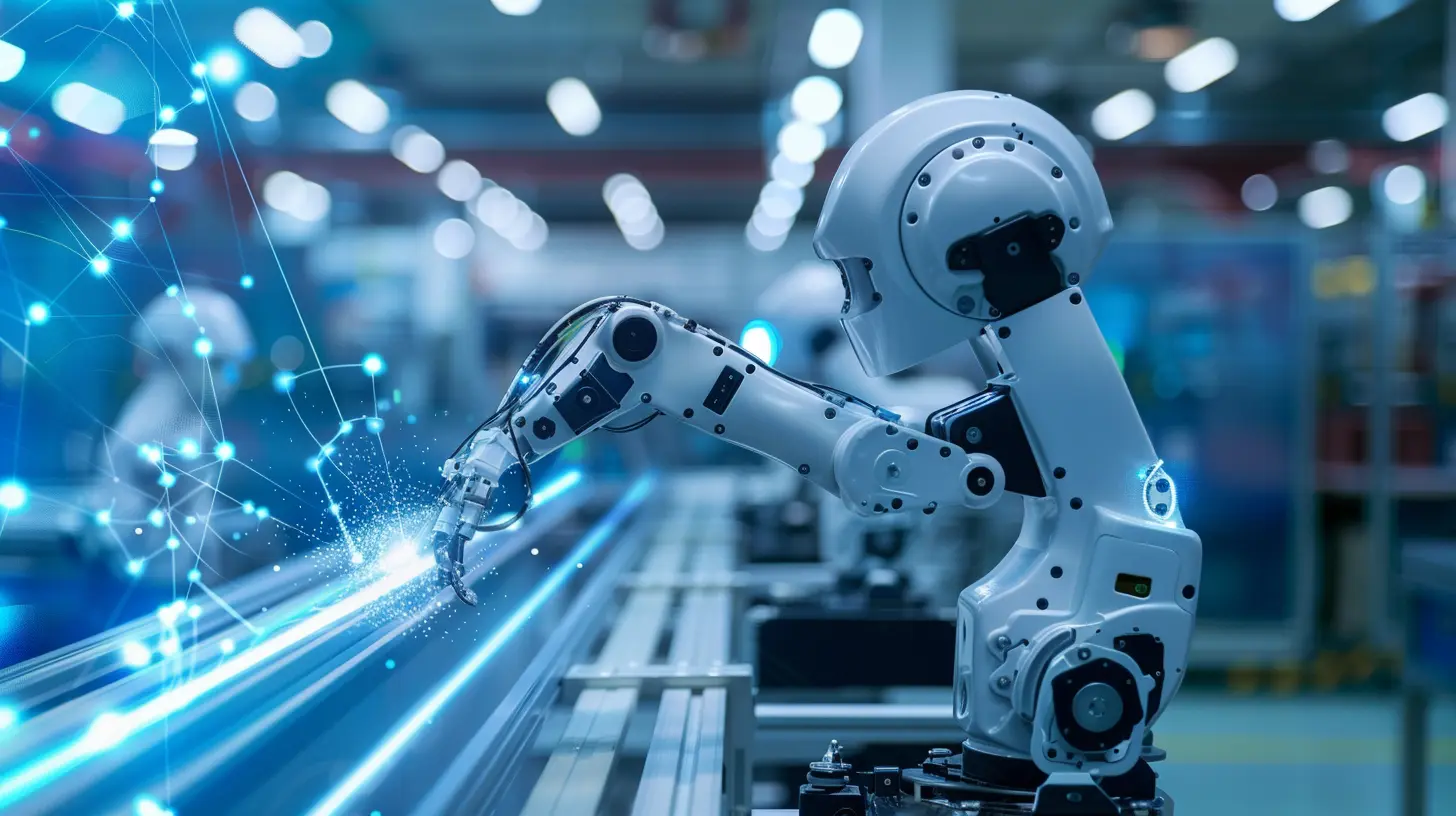

Let’s rewind a bit.Back in the day, manufacturing was all about manual labor. It was sweat, skill, and sheer human effort. Then came the Industrial Revolution, and with it, machines entered the picture. Fast forward to the 21st century, and now we’re talking about smart factories, robotic arms, AI-powered systems, and machines that practically think for themselves.

Automation isn’t just adding machines to the process—it’s about integrating intelligent systems that can operate, adjust, and improve without human interference. That’s a huge leap.

So, What Exactly is Automation?

Let’s keep it simple. Automation in manufacturing means using technology to perform tasks that were previously done by humans. These tasks can range from basic repetitive actions like assembly and packaging to more complex operations involving data analysis, quality control, and predictive maintenance.Imagine a robot arm assembling car parts 24/7 without taking a coffee break. Or a software system that monitors thousands of sensors on a production line and tweaks performance in real-time. That's automation in action!

Why Is Automation Taking Over?

You might wonder, “Why all the buzz around automation?” Well, here’s the deal:- Efficiency Boost: Automation makes things faster. Period. Machines don’t need breaks, sleep, or vacation—they just keep going.

- Cost Savings: Sure, the upfront investment can be huge, but in the long run? Companies save big on labor, waste, and downtime.

- Precision & Quality: Humans make mistakes. Machines, when properly programmed, don’t. That means products are more consistent and defects go down.

- Data-Driven Insights: Automation isn’t just physical—it’s digital too. Smart systems collect and analyze data to help managers make better decisions.

Key Areas Where Automation is Making Waves

Let’s break it down. Here are the major areas within manufacturing where automation is having a massive impact:1. Assembly Lines

This is the classic case. Robots on the assembly line can perform repetitive tasks faster and more accurately than a human ever could. Think welding, screwing, painting, and packing.2. Quality Control

Instead of relying on human eyeballs to catch defects, companies now use AI-powered cameras and sensors. These systems detect flaws at microscopic levels—and they do it in real-time.3. Inventory Management

Autonomous drones and smart software handle inventory in massive warehouses. They scan, track, and report stock levels without human help.4. Predictive Maintenance

Imagine a machine telling you before it breaks down that it needs repair. IoT sensors and predictive algorithms now make this possible, saving companies from costly unplanned downtime.5. Logistics and Supply Chain

Automated vehicles, smart routing algorithms, and real-time tracking systems are dramatically improving the way goods move from one place to another.Real-World Automation Tech You Should Know About

It’s not just a buzzword. Here are some real technologies currently transforming the industry:- Collaborative Robots (Cobots): These are robots designed to work alongside humans safely. They’re not here to take over, but to help.

- Industrial Internet of Things (IIoT): A network of connected sensors, devices, and machines that communicate and improve efficiency across the board.

- Artificial Intelligence (AI) and Machine Learning (ML): These aren’t just for self-driving cars. In manufacturing, they help with demand forecasting, predictive maintenance, and quality analysis.

- 3D Printing: Also known as additive manufacturing, this tech allows for rapid prototyping and custom production, all with minimal waste.

How Automation is Affecting Jobs—Is the Robot Really Taking Over?

Let’s talk about the elephant in the room: jobs.There’s no denying that automation is replacing some human labor. Repetitive, mundane tasks are increasingly being handled by machines. But here’s another side to the story—automation is also creating jobs. Just different kinds of jobs.

Instead of manual labor, there’s now a rising demand for engineers, programmers, data analysts, and maintenance techs who can manage and improve automated systems. So yes, some roles are disappearing, but others are being born.

It’s kind of like the elevator operator disappearing when automated buttons came along. At the time, it was scary. But the world moved on and new opportunities emerged.

Benefits That Go Beyond the Factory Floor

Here’s the thing—automation doesn’t just help manufacturers. It helps customers, the environment, and even society at large. Let’s take a look:Faster Product Delivery

Automation drastically shortens production cycles. That means customers get products quicker, and companies can better handle demand spikes without chaos.Improved Safety

When machines handle dangerous tasks, workplace injuries drop drastically. That’s a win for everyone.Sustainable Manufacturing

Many smart systems focus on minimizing waste and optimizing energy use. That not only cuts costs but is also better for the planet.Customization at Scale

Remember when custom orders took ages? With automation, mass customization (yes, that’s a thing) is now possible. You get personalized products without sacrificing speed or cost.

The Challenges—Because Nothing’s Perfect

Of course, automation isn’t all sunshine and rainbows. There are bumps on the road:- High Initial Investment: Not every company can afford to automate right away. The tech isn’t cheap.

- Training and Upskilling: Workers need to learn new skills to work with advanced systems. That takes time and effort.

- Cybersecurity Risks: Connected systems are vulnerable to hacking if not properly protected.

- Resistance to Change: Let’s be real—people don’t like big changes. Automation can face pushback from employees and even managers worried about disruption.

Still, most manufacturing leaders agree: the benefits far outweigh the challenges—if you do it right.

Future Trends: Where Are We Headed?

Curious about what’s coming next? Here are some automation trends that are gaining momentum:Hyper-Automation

That’s automation on steroids. It combines AI, ML, RPA (Robotic Process Automation), and more to create fully automated ecosystems.Digital Twins

This one’s cool. It’s a virtual replica of a physical system, allowing manufacturers to test changes in a simulated world before touching the real thing.Edge Computing

Instead of sending data to a distant server, machines process it right on the factory floor. That means faster decisions and smarter automation.Lights-Out Manufacturing

Imagine a factory with no humans at all—just machines working in the dark. This is already happening in some industries, especially in semiconductor and electronics manufacturing.

How Can Businesses Get Started?

If you're a business owner or leader in manufacturing, you might be asking, “Okay, but how do we start automating?” Good question. Here’s a simple roadmap:1. Analyze Your Needs: Figure out which processes are ripe for automation. Start small—maybe with inventory tracking or quality checks.

2. Set Clear Goals: What do you want to improve? Speed? Quality? Cost?

3. Choose the Right Tech: Not every solution fits every business. Do your research or bring in a consultant.

4. Train Your Team: Upskill your people so they can work with and manage automation tools.

5. Monitor and Adapt: Automation isn’t a set-it-and-forget-it deal. Keep refining it to get better results.

Final Thoughts

Automation is not the future of manufacturing—it’s the present. It's changing the rules, raising the bar, and opening new doors for what’s possible in this age-old industry. Whether you’re a business leader, a worker, or just a curious reader, one thing’s for sure: ignoring automation isn’t an option anymore.Sure, the shift comes with challenges, but the opportunity it brings? Massive. Automation, when done right, makes factories smarter, products better, and businesses stronger.

So, is your business ready to ride the wave? Or are you still standing on the shore?

all images in this post were generated using AI tools

Category:

Business TrendsAuthor:

Caden Robinson

Discussion

rate this article

2 comments

Parker Castillo

Automation is the future of manufacturing.

November 26, 2025 at 11:28 AM

Tempest Bass

Great insights on automation’s impact in manufacturing! It's fascinating to see how technology is streamlining processes and boosting efficiency. Excited to witness what the future holds!

July 27, 2025 at 2:16 AM

Caden Robinson

Thank you for your kind words! I'm glad you enjoyed the insights—exciting times ahead for manufacturing with automation!